©2018 Guangzhou Hengde Construction Technology Co., Ltd.

TEL:13924139149

Hotline:400-831-9091

E-mail:gzhengde@163.com

ADD:Foshan rich Ann industrial zone rich even road no. 25

CONTACT US

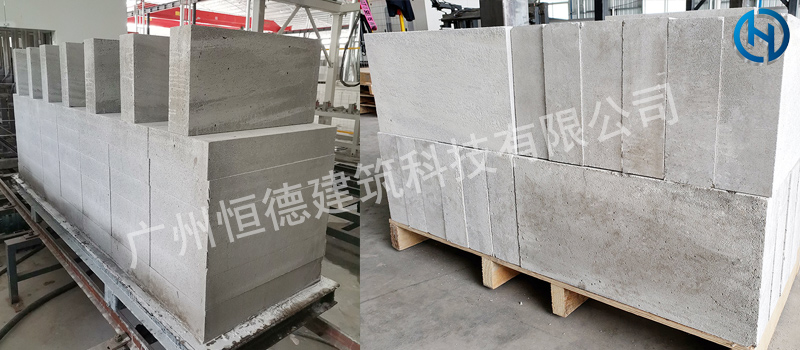

Environmentally friendly brick production equipment

This is a new type of large-scale comprehensive building energy-saving waste green brick production equipment, using German advanced environmental brick production technology, high product strength and low cost. Industrial waste, fly ash, slag, construction waste and other materials can be used to make light bricks, steam-free aerated blocks, energy-saving and environmentally friendly bricks and other products.

First, the characteristics of environmentally friendly brick production equipment

1. Green and environmental protection: This environmentally-friendly brick technology is an important scientific research achievement in the application of wall materials, enriching the variety of new wall materials and highlighting the “characteristics” of environmental protection. The process technology and equipment of this project deal with industrial waste such as fly ash, coal gangue and electric lime, and the production process is simple and fast.

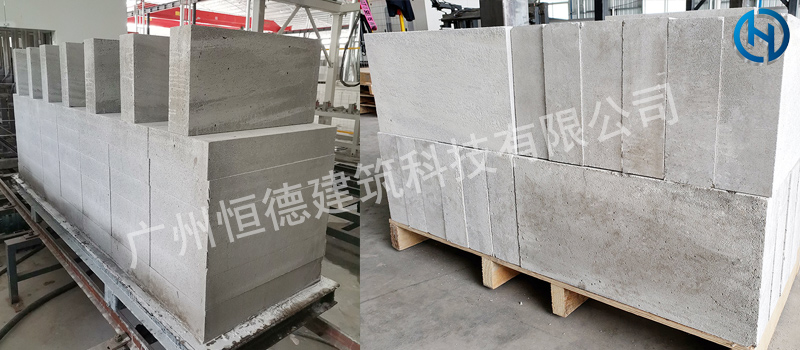

2. Cost advantage: The raw materials required for the production of environmentally-friendly brick equipment are extensive, and the materials are used nearby. Fly ash, river sand, slag, slag, tailings sand, stone powder, etc. can be used as raw materials (the same can be produced)。

3. Energy saving and emission reduction: The project is a fully automatic production line, which saves a lot of energy and does not require traditional autoclave “steaming”, which can greatly save energy and burn coal.

4. New technology and new technology: The exclusive cement foaming technology--"primary kiln" is used to make the block have independent closed micropores, which makes the internal pore shape and porosity of the environmental protection block difficult to control. The solution can greatly reduce the water absorption rate of the block bricks, thereby improving the freeze-thaw resistance and ensuring product quality.

5. Equipment advantages: using computer touch screen control system, precise automatic metering, automatic feeding, using a new 360-degree rotary cutting saw technology, the entire production process does not discharge waste water and smoke, no pollution. Equipped with the company to develop a "maintenance process" to reduce costs and extend production time and efficiency. (This production line is divided into single mode, dual mode and three mode three types)

6. Advantages of cutting saw: high-strength block brick cutting, fast speed, neat appearance, standard size, no shortage of corners and other angles.

Second, Plants, hydropower and raw materials required for the project:

The production line adopts automatic batching and electronic metering, with high degree of automation, accurate measurement and precise operation control. The molding equipment has the characteristics of reasonable structure design, convenient production operation, short molding cycle, high production efficiency and good product quality. The complete set of equipment includes: electronic metering device, loading system, mixing system, mixing system, pumping system, control system, cutting system and so on.

1. Building part:

1. Storage height 3m (placement admixture) area 50-100m2

2. Semi-open factory building height 5m (place production line, raw materials) area 200-500m2

3. Product maintenance area (forming and curing products) Area 2000m2-----4000m2

4. Finished product stacking area (stacked finished product) Area 1500m2-----3000m2

2. Hydropower part:

Total power of the plant: 100-200KW or so Production water: 2400m3/month

3. Production of raw materials:

1. Cement: 425R Portland cement 2. Fly ash raw ash (optional) 3. Stone powder fine powder (optional) 4. Sand mud content ≤ 2% (optional) 5. Slag powder fine powder (optional additive ( The company provides)

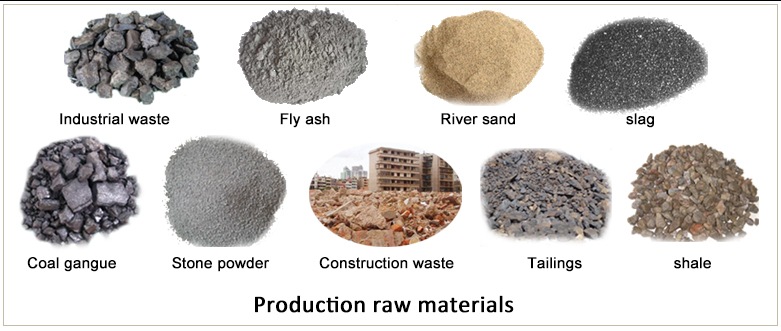

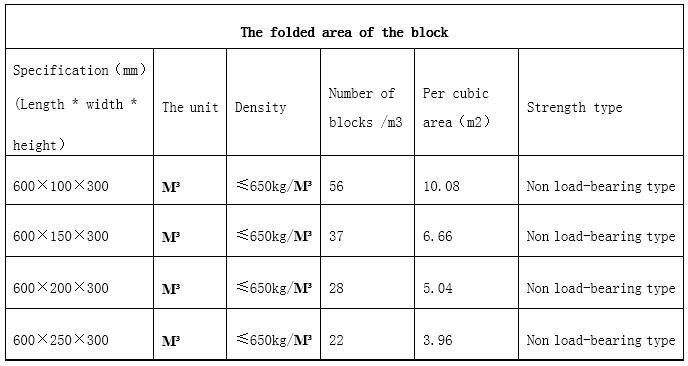

Third, the advantages and parameters of environmentally friendly bricks

Lightweight, heat-insulating, heat-insulating, sound-proof, environmentally friendly, fire-resistant, drowning, easy to construct

Environmental brick application range:

It is used in buildings in earthquake-resistant areas; as an external wall for building multi-storey buildings, as an infill wall for frame structures; as an inner and outer wall for high-rise frame buildings; it can also be used as an external thermal insulation material for walls, to adapt to buildings in severe cold areas. Suitable for residential, apartment buildings, office buildings; public buildings, schools, libraries, hospitals, banks, clubs, restaurants; sports and entertainment facilities, football stadiums, stadiums, swimming pools and other modern buildings.